Enhanced Flexible Mold Lifetime for Roll‐to‐Roll Scaled‐Up Manufacturing of Adhesive Complex Microstructures

Bioinspired Microstructured Adhesives with Facile and Fast Switchability for Part Manipulation in Dry and Wet Conditions

Smart Materials for manipulation and actuation of small-scale structures

3D nanofabrication of various materials for advanced multifunctional microrobots

Liquid Crystal Mesophase of Supercooled Liquid Gallium And Eutectic Gallium–Indium

Machine Learning-Based Pull-off and Shear Optimal Adhesive Microstructures

Information entropy to detect order in self-organizing systems

Individual and collective manipulation of multifunctional bimodal droplets in three dimensions

Microrobot collectives with reconfigurable morphologies and functions

Self-organization in heterogeneous and non-reciprocal regime

Biomimetic Emulsion Systems

Giant Unilamellar Vesicles for Designing Cell-like Microrobots

Bioinspired self-assembled colloidal collectives drifting in three dimensions underwater

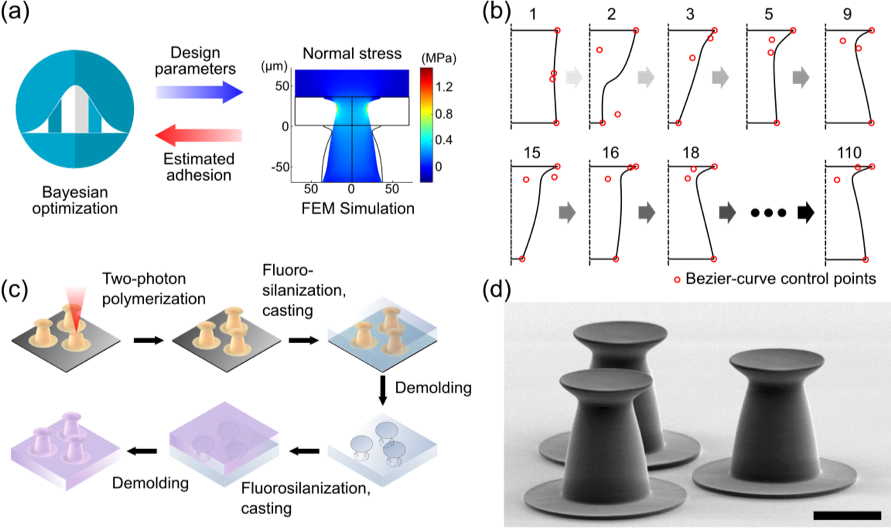

Machine Learning-Based Pull-off and Shear Optimal Adhesive Microstructures

Bioinspired fibrillar structures are promising for a wide range of disruptive adhesive applications. Especially micro/nano fibrillar structures on gecko toes can have strong and controllable normal and shear adhesion on a wide range of surfaces with residual-free, repeatable, self-cleaning, and other unique features. Synthetic dry fibrillar adhesives inspired by such biological fibrils are optimized in different aspects to increase their performance. Previous fibril designs for pull-off and shear optimization are limited by predefined standard shapes in a narrow range primarily based on human intuition, which restricts their maximum performance. This project combines machine learning-based optimization and finite-element-method-based simulations to find pull-off-optimized[] and shear-optimized[

] adhesive microstructure designs automatically. In addition, fabrication limitations are integrated into the simulations to have more experimentally relevant results. The computationally discovered pull-off and shear-optimized structures are fabricated, experimentally validated, and compared with the simulations. The results show that the computed pull-off and shear-optimized microstructures perform better than the predefined standard fibril designs. This design optimization method can be used in future real-world pull-off and shear-based gripping or nonslip surface applications, such as robotic pick-and-place grippers, climbing robots, gloves, electronic devices, and medical and wearable devices.

Members

Publications