3D nanofabrication on complex seed shapes using glancing angle deposition

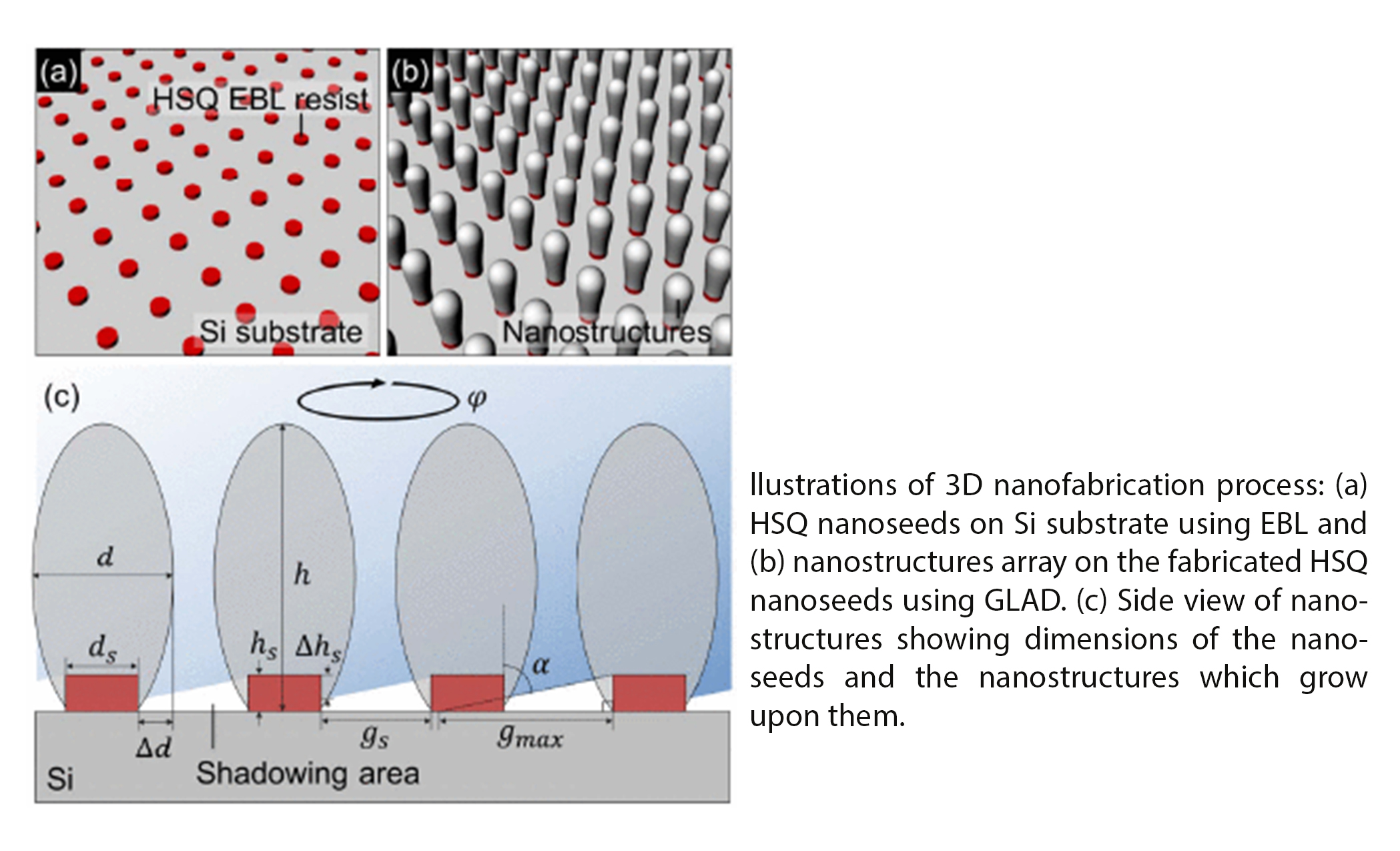

Three-dimensional (3D) fabrication techniques promise new device architectures and enable the integration of more components, but fabricating 3D nanostructures for device applications remains challenging. Recently, we have performed glancing angle deposition (GLAD) upon a nanoscale hexagonal seed array to create a variety of 3D nanoscale objects including multicomponent rods, helices, and zigzags [1]. Here, in an effort to generalize our technique, we present a step-by-step approach to grow 3D nanostructures on more complex nanoseed shapes and configurations than before. This approach allows us to create 3D nanostructures on nanoseeds regardless of seed sizes and shapes.

| Author(s): | Hyeon-Ho, Jeong and Mark, Andrew G. and Gibbs, John G. and Reindl, T. and Waizmann, U. and Weis, J. and Fischer, Peer. |

| Book Title: | 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS) |

| Pages: | 437-440 |

| Year: | 2014 |

| Month: | January |

| Day: | 30 |

| Bibtex Type: | Conference Paper (inproceedings) |

| Address: | Piscataway, NJ, USA |

| DOI: | 10.1109/MEMSYS.2014.6765670 |

| State: | Published |

| URL: | 10.1109/MEMSYS.2014.6765670 |

| Electronic Archiving: | grant_archive |

BibTex

@inproceedings{6765670,

title = {3D nanofabrication on complex seed shapes using glancing angle deposition},

booktitle = {2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS)},

abstract = {Three-dimensional (3D) fabrication techniques promise new device architectures and enable the integration of more components, but fabricating 3D nanostructures for device applications remains challenging. Recently, we have performed glancing angle deposition (GLAD) upon a nanoscale hexagonal seed array to create a variety of 3D nanoscale objects including multicomponent rods, helices, and zigzags [1]. Here, in an effort to generalize our technique, we present a step-by-step approach to grow 3D nanostructures on more complex nanoseed shapes and configurations than before. This approach allows us to create 3D nanostructures on nanoseeds regardless of seed sizes and shapes.},

pages = {437-440},

address = {Piscataway, NJ, USA},

month = jan,

year = {2014},

slug = {6765670},

author = {Hyeon-Ho, Jeong and Mark, Andrew G. and Gibbs, John G. and Reindl, T. and Waizmann, U. and Weis, J. and Fischer, Peer.},

url = {10.1109/MEMSYS.2014.6765670},

month_numeric = {1}

}