Data-efficient Autotuning with Bayesian Optimization: An Industrial Control Study

arXiv (PDF)

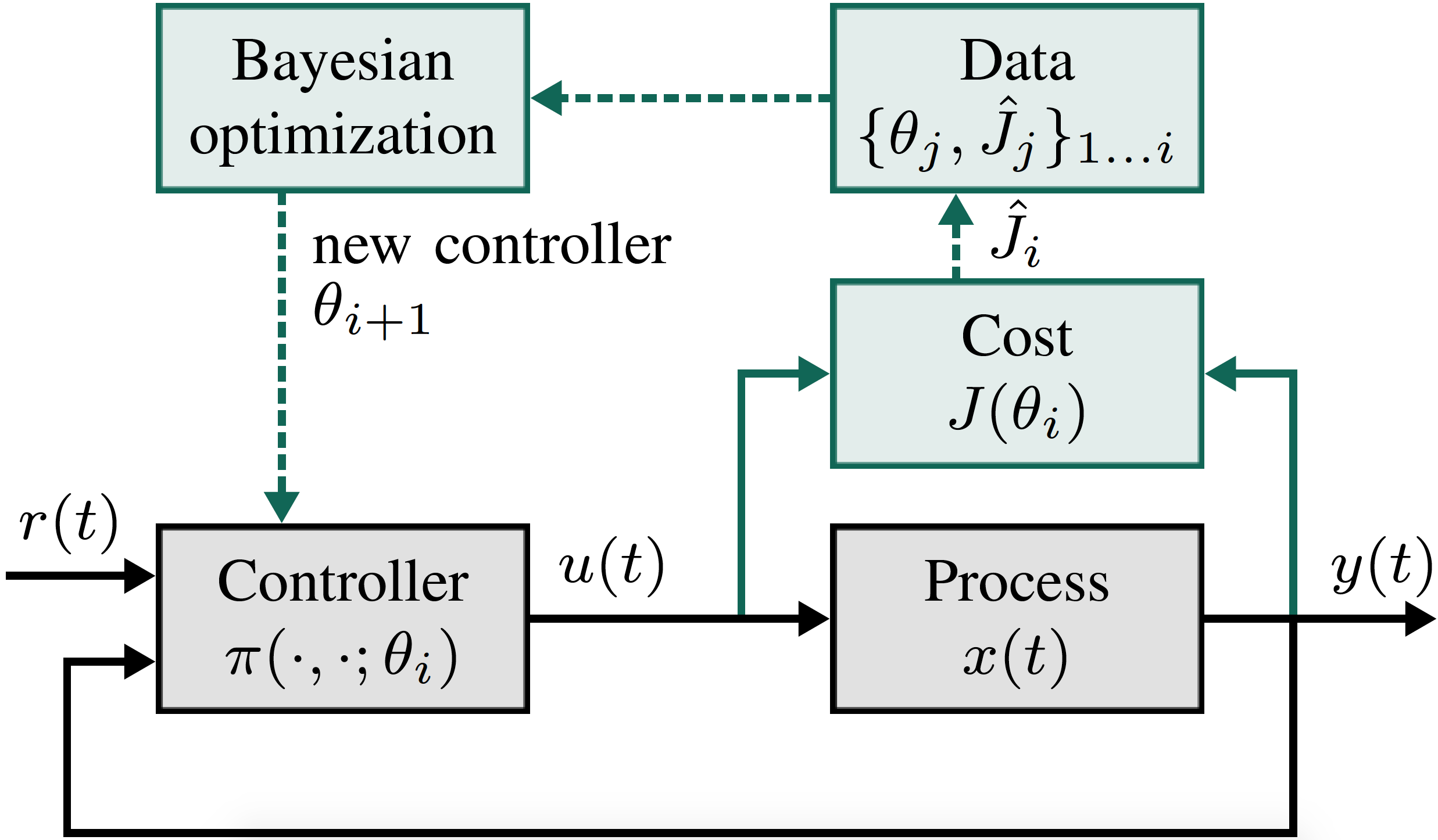

Bayesian optimization is proposed for automatic learning of optimal controller parameters from experimental data. A probabilistic description (a Gaussian process) is used to model the unknown function from controller parameters to a user-defined cost. The probabilistic model is updated with data, which is obtained by testing a set of parameters on the physical system and evaluating the cost. In order to learn fast, the Bayesian optimization algorithm selects the next parameters to evaluate in a systematic way, for example, by maximizing information gain about the optimum. The algorithm thus iteratively finds the globally optimal parameters with only few experiments. Taking throttle valve control as a representative industrial control example, the proposed auto-tuning method is shown to outperform manual calibration: it consistently achieves better performance with a low number of experiments. The proposed auto-tuning framework is flexible and can handle different control structures and objectives.

| Author(s): | Matthias Neumann-Brosig and Alonso Marco and Dieter Schwarzmann and Sebastian Trimpe |

| Links: | |

| Journal: | IEEE Transactions on Control Systems Technology |

| Volume: | 28 |

| Number (issue): | 3 |

| Pages: | 730--740 |

| Year: | 2020 |

| Month: | May |

| Project(s): | |

| Bibtex Type: | Article (article) |

| DOI: | 10.1109/TCST.2018.2886159 |

| State: | Published |

| Electronic Archiving: | grant_archive |

BibTex

@article{NeuMarSchTri18,

title = {Data-efficient Autotuning with Bayesian Optimization: An Industrial Control Study},

journal = {IEEE Transactions on Control Systems Technology},

abstract = {Bayesian optimization is proposed for automatic

learning of optimal controller parameters from experimental

data. A probabilistic description (a Gaussian process) is used

to model the unknown function from controller parameters to

a user-defined cost. The probabilistic model is updated with

data, which is obtained by testing a set of parameters on the

physical system and evaluating the cost. In order to learn fast,

the Bayesian optimization algorithm selects the next parameters

to evaluate in a systematic way, for example, by maximizing

information gain about the optimum. The algorithm thus iteratively

finds the globally optimal parameters with only few

experiments. Taking throttle valve control as a representative

industrial control example, the proposed auto-tuning method is

shown to outperform manual calibration: it consistently achieves

better performance with a low number of experiments. The

proposed auto-tuning framework is flexible and can handle

different control structures and objectives.},

volume = {28},

number = {3},

pages = {730--740},

month = may,

year = {2020},

slug = {bayesianindustrial2018},

author = {Neumann-Brosig, Matthias and Marco, Alonso and Schwarzmann, Dieter and Trimpe, Sebastian},

month_numeric = {5}

}